Grass Drying--Shouchuang Mesh Belt Dryer

The mesh belt dryer is an efficient solution for drying forage crops. Utilizing a multi-layer structure, it allows for continuous drying of various grasses, ensuring even heat distribution. With high processing capacity, it can handle large volumes. The design minimizes drying costs while maximizing energy efficiency, ensuring quality retention in the final product. ShouChuang mesh belt dryer is customizable to meet specific requirements, accommodating different materials and environmental conditions, making it a versatile choice for forage drying needs.

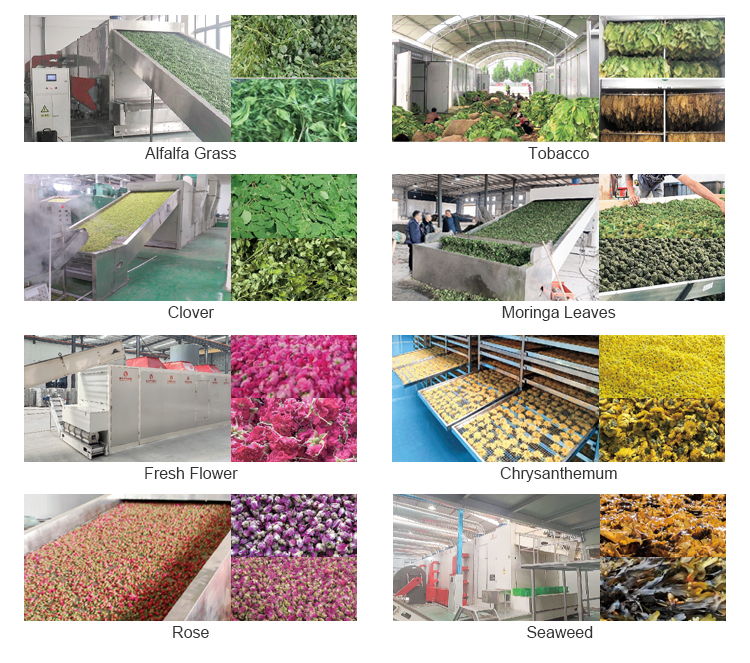

Common Types of Grass That Can Be Dried

Our drying machine effectively enhances the quality and economic value of dried forage, supporting large-scale processing while saving time and energy. Additionally, the drying machine can be paired with clean energy as a heat source, ensuring energy efficiency, environmental friendliness, and higher safety standards. If the materials you are interested in are not listed above, please feel free to contact us for more details.

Similar Materials Drying Display

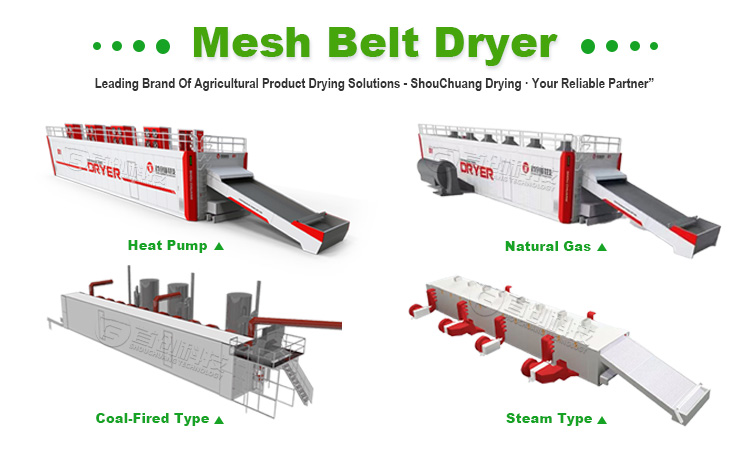

Multiple Heat Sources Available

The mesh belt dryer offers a variety of heat source options, including heat pumps, natural gas, steam, and coal. This flexibility allows for tailored solutions to meet specific customer needs and operational conditions. Each heat source presents unique advantages in terms of efficiency, cost-effectiveness, and environmental impact.

Working principle

The dryer is a dynamic-drying multi-layer mesh belt dryer. The mesh belt dryer through the air supply system to the air according to the material drying process requirements into the drying room.At the same time, the material through the automatic laying device, cleaning machine, slicing machine, lifting machine into the drying room, and in the drying room along the horizontal direction to do section rotation, do "S" shaped operation, while the hot air vertically through the material, high heat transfer efficiency, so as to achieve the purpose of drying material pieces.

| |

1. Feeding Conveyor | 304 stainless steel food-grade conveyor mesh belt is available in customizable materials and apertures. The default size is 12 mesh with a wire diameter of 0.5 mm; |

2. Paving Device | The patented design prevents raw materials from piling up at the feeding port, ensuring consistent material color and drying effect; |

3. Dehumidification Device | Unique patented design, customized moisture removal method, fast water removal, reduced energy consumption and drying time; |

4. External Air Duct | The innovative waste heat recovery system connects the main fan and dehumidification fan via air pipes, allowing simultaneous water removal and heat recycling |

5. Internal Structure | Invention patent design, multi temperaturezone pipe network air supply structure torealize layered and segmented air supply; |

6. Air Fan | The fan is manufactured by fully automatic robotand designed by precise size of laser cuttingmachine imported from Germany; |

7. Control System | Can realize remote control oftemperature control speed, data control ofmobile terminal and one key switch of the machine; |

8. Discharge Device | Fully automatic design, materials automatically drop and transport after processing, customers can decide to bag or the next step of processing. |

Mesh Belt Machine Parameter

Due to different material types and different material forms, the number of layers and length of the mesh belt machine need to be designed according to the specific material processing capacity and the specific floor space. Under normal circumstances, the maximum processing capacity, such as fruit peel, can reach 100 tons per day, the highest number of mesh belt machine layers can reach 8 layers, and the longest length is 50 meters;

Model | 5HDW4-6 | 5HDW4-8 | 5HDW4-10 | Other Size |

Mesh belt layers | 4 layers | 4 layers | 4 layers | 4 layers |

Use temperature ( ℃) | 30-80 | 30-80 | 30-80 | 30-80 |

Paving thickness( mm) | 30-120 | 30-120 | 30-120 | 30-120 |

Belt width( mm) | 1840/2760 | 1840/2760 | 1840/2760 | 1840/2760 |

Total Power(Kw) | 18-33 | 33-44 | 40.5-49 | Customized |

Effective drying area(m3 ) | 39 | 53 | 67 | Customized |

Operating temperature | 40-85℃ | | | |

Overall Dimension (mm) | 16000*8000*3200 | 18000*8000*3200 | 20000*8000*3200 | Customized |

Drying cycle (hours) | 1-15h/coutinous drying | | | |

control method | PLC cotrol system | | | |

Conveyor belt material | SS304 or according to the drying materials to choose | | | |

Material Description | The parts in contact with the material are all 304 stainless steel or food grader rubber strips | | | |

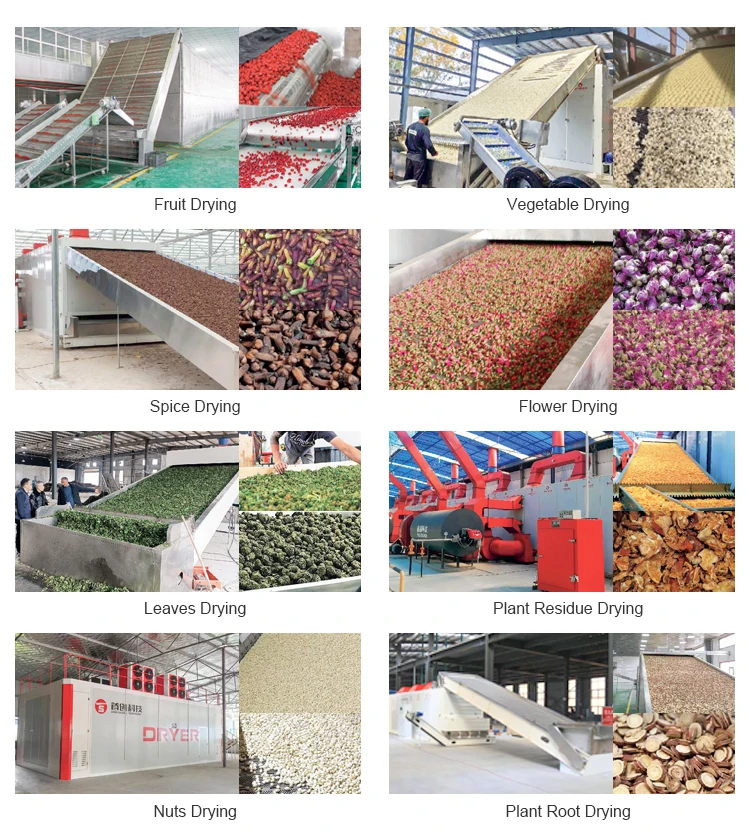

Mesh Belt Dryer's Application

Moreover, our belt-type drying machine is also capable of drying a variety of materials, including fruits, vegetables, spices, herbs, nuts, coffee beans, fruit pomace, and coffee grounds, etc.

Company Profile

Founded in 1972, Sichuan Shouchuang is one of the largest agricultural machinery manufacturers in China and a national high-tech enterprise. Relying on a large number of experimental support and data analysis, we have established a database of more than 400 kinds of materials, customized drying process design for customers' pain points and difficulties, and landed more than 1000 million projects. Our factory advantages are as follows:

50 + years of drying experience;

200+ managers, sales and technicians;

30000+ square meter factory area;

3+ manufacturing bases (Sichuan, Foshan, Guizhou province);

400+ material's database;

70+ national patents and software copyrights;

60+ exported to about 60 countries;

6000+ domestic and foreign customer cases;

Drying Solutions Available

We can provide drying solutions in different dimensions, from small scale drying operations and initial product drying to deep drying and intelligent factory drying;Small-scale Operations Solutions:Having multiple product lines to meet different types of needs;

Business Solutions :Provide solutions from initial drying to deep drying for various products;

Industrial Solutions:Analyze the local market data and provide suggestions on the layout of the drying industry in line with the development advantages;

Intelligent Factory Solution:Virtual simulation,3D mapping, traceability MES, ERP, PLM;

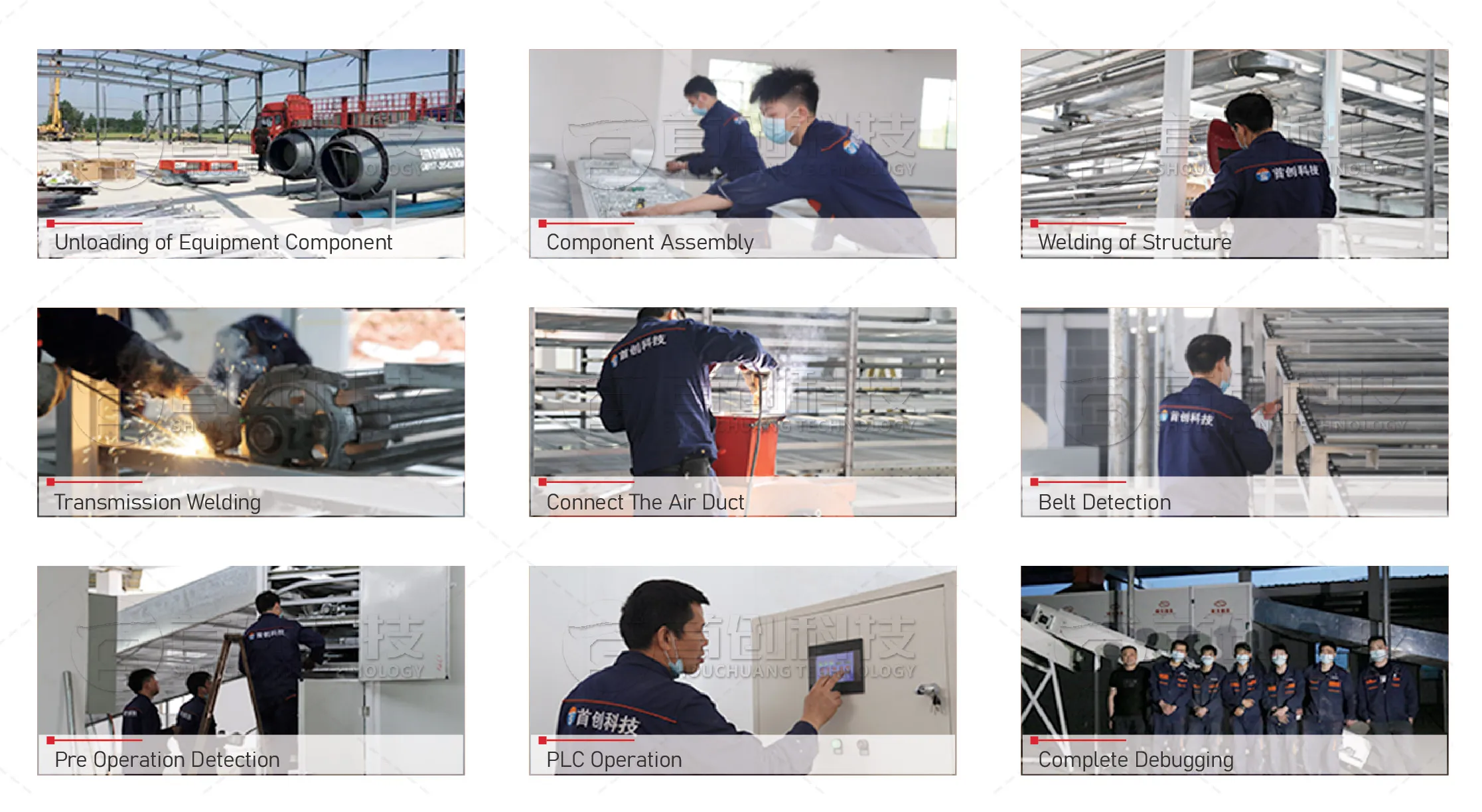

About Mesh Belt Dryer Installation

For the installation of the mesh belt dryer machine, we can provide the following three ways: 1. Sending its own professional installation engineers: This method is suitable for most customers; 2. Telephone and video installation guidance: This method is suitable for customers with professional engineers; 3. Local agent professional installation engineer: This method is suitable for the local qualified to become the first network belt machine agent; Note: Recruit global agents Agent qualification requirements: 1. Purchased and used the shouchuang mesh belt dryer 3 or more; 2. Own engineer team that can install dryer; If you are interested in this and meet the above two points, please contact us!

According to the transportation distance and different modes of transportation, choose the nude, fixed packaging or hardcover to reduce the transportation cost and increase the customer experience, so as to better complete the transportation delivery.

Company Advantages

· ShouChuang conveyor dryer machine is manufactured using automation technology.

· Our conveyor dryer machine have advantages of high quality and low cost for maintenance.

· ShouChuang is in the hands of the development, design, sales and service of conveyor dryer machine.

Company Features

· Sichuan Nanchong Shouchuang Technology Development Co., Ltd. makes improved conveyor dryer machine products and offers superior service.

· Sichuan Nanchong Shouchuang Technology Development Co., Ltd. has several experienced sales and technical engineers.

· We aim to achieve measurable sustainability targets – reducing environmental impact and protecting the extraordinarily rich natural resources that our country enjoys. Check it!

Application of the Product

ShouChuang's conveyor dryer machine can be used in multiple scenes.

Our solutions are specially set up to the customer's actual situation and needs to ensure that the solutions provided to the customer are effective.