ShouChuang-Leading Continuous Conveyor Belt Dryer Manufacturer For Agricultural Product Since 1972.

From Land to Shelf: Streamlining the Process with Plant Drying Machines

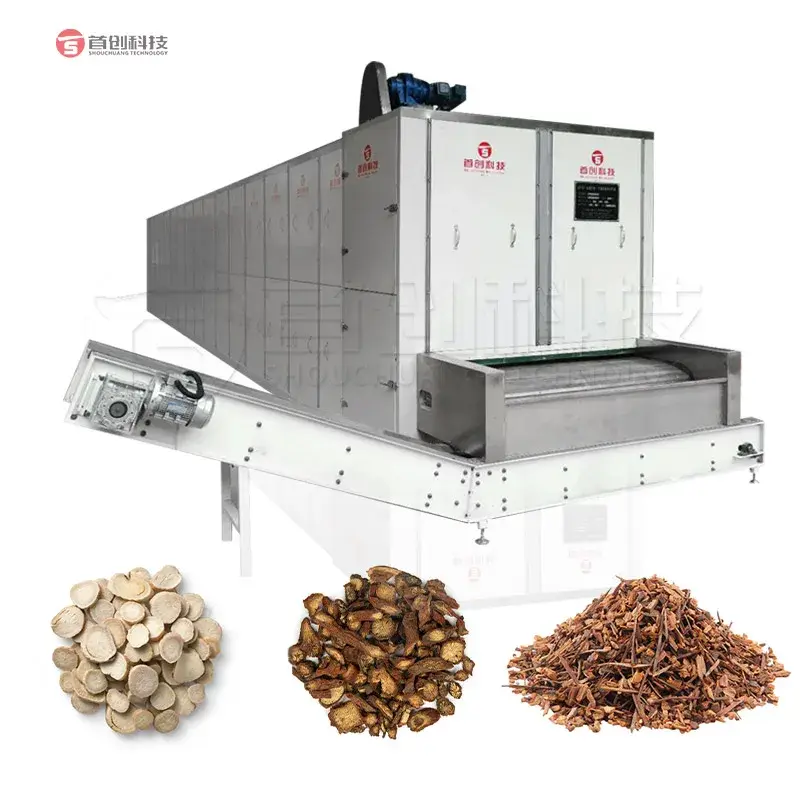

From the fields to the shelves, plant drying machines are revolutionizing the post-harvest phase, ensuring that crops reach consumers in optimal condition. The journey from the land to the shelf is a complex process that requires precision, efficiency, and quality control. For modern agricultural and food processing industries, this transition is no easy feat, especially given the diverse range of crops and their unique characteristics. Enter plant drying machinesinnovative solutions that are transforming the post-harvest handling industry.

Bridging the Gap Between Harvesting and Processing

Plant drying machines have become an indispensable part of the modern agricultural supply chain. They play a pivotal role in the transition from harvesting to processing, a phase that is both labor-intensive and prone to spoilage. The drying process is essential for maintaining product quality, extending shelf life, and ensuring food safety. Without these machines, many crops would degrade rapidly, leading to significant losses for growers and processors alike.

Consider John, a farmer who faced these challenges firsthand. Traditional drying methods often resulted in mold, bacteria, and uneven drying, leading to wasted produce and financial losses. After discovering plant drying machines, John invested in a system that automated the drying process, ensuring consistent results and significantly reducing spoilage. This not only improved his crop's quality but also boosted his profitability, allowing him to expand his operations and supply more produce to local markets.

The Role of Plant Drying Machines in Modern Agriculture

Plant drying machines are more than just drying devices; they are advanced machines that are revolutionizing the way crops are processed. These machines use a variety of drying techniques, including thermal air drying, infrared drying, and vacuum drying, each with its own advantages and applications. The choice of drying method depends on the type of crop, its moisture content, and the desired outcome.

One of the key advantages of plant drying machines is their ability to achieve uniform drying. Traditional methods often resulted in uneven drying, leading to some parts of the crop being over-dried while others remained wet. Plant drying machines, on the other hand, use precise temperature and humidity controls to ensure even drying across the entire product. This not only preserves the crop's quality but also extends its shelf life, making it more marketable and valuable.

Another significant benefit of these machines is their automation capabilities. Modern plant drying machines are equipped with advanced monitoring systems that allow operators to track the drying process in real-time. This level of control eliminates the need for constant human supervision, reducing labor costs and increasing efficiency. Additionally, many machines include automated cleaning mechanisms, ensuring that the drying process remains hygienic and eliminating the risk of contamination.

Plant drying machines can also contribute to significant cost savings. Studies have shown that these machines can reduce drying time by up to 50%, depending on the crop and drying method. This not only speeds up the processing cycle but also allows for more frequent batch processing, increasing throughput and reducing waiting times. By minimizing energy consumption, these machines contribute to lower operational costs and a more sustainable farming operation.

Impact of Post-Harvest Management on Product Quality

Post-harvest management is a critical component of the food supply chain, and plant drying machines play a vital role in this phase. Proper drying ensures that crops remain fresh, reducing the risk of spoilage and contamination. It also preserves essential nutrients and vitamins, maintaining the product's quality and nutritional value.

A local farm that implemented plant drying machines saw a marked improvement in the quality and consistency of its produce. Before the introduction of these machines, the farm faced significant challenges with spoilage, particularly with fruits and vegetables that are highly perishable. After adopting plant drying machines, the farm not only saw a noticeable difference in the freshness and appearance of the crops but also was able to sell its products at premium prices. This success not only boosted the farm's profitability but also contributed to its reputation as a quality producer, attracting more customers and investment.

Enhancing Efficiency Through Automated Plant Drying Processes

Automation is a key feature of modern plant drying machines. These machines are designed to streamline operations, reduce human error, and maximize efficiency. The ability to control temperature and humidity with precision ensures consistent drying, while integrated monitoring systems provide real-time insights into the drying process. This level of control eliminates the need for constant supervision, saving time and reducing the risk of human error.

Moreover, plant drying machines offer versatility, suitable for a wide range of crops such as wheat, corn, soybeans, and specialty crops like organic vegetables. These machines can be tailored to meet the specific needs of each product, ensuring optimal drying conditions while maintaining the quality of the produce.

By automating the drying process, plant drying machines also reduce labor costs and increase productivity. Operators can focus on monitoring and controlling the drying process, rather than spending time on manual tasks like sorting or handling. This allows for more frequent and consistent drying, increasing the overall efficiency of the operation and reducing downtime.

Plant drying machines also contribute to reducing food waste. By ensuring consistent drying and reducing spoilage, these machines help farmers and processors meet market demands and improve overall sustainability. This is particularly important in the context of global food security, where efficient post-harvest handling plays a critical role.

Economic Benefits and Cost Savings

Investing in plant drying machines is a smart and strategic choice for both large and small farms. These machines can save significant amounts of money in terms of reduced labor, lower energy consumption, and increased productivity. For example, studies have shown that plant drying machines can save farmers up to 30% on operational expenses by reducing labor costs and energy consumption.

By automating the drying process, these machines eliminate the need for labor-intensive tasks, reducing the need for human intervention. This not only saves time but also reduces the risk of human error, resulting in higher quality products. Additionally, the energy efficiency of these machines can lead to substantial cost savings, especially in large-scale operations where energy consumption can be substantial.

Sealing the Deal with Plant Drying Machines

Plant drying machines are more than just machines for drying crops; they are essential components of modern agricultural and food processing operations. By automating the drying process, improving efficiency, and ensuring consistent quality, these machines are helping farmers and processors overcome the challenges of post-harvest handling. They are enabling operations to move from the field to the shelf more quickly and efficiently, ensuring that crops reach consumers in optimal condition.

As the agricultural and food processing industries continue to evolve, plant drying machines will play an increasingly important role in shaping the future of the industry. With advancements in technology, from infrared drying to nanotechnology, these machines are poised to offer even greater efficiencies and innovations in the coming years. Whether it's through improved drying methods, automation, or advanced technologies, plant drying machines are here to stay, and their impact on the industry will only grow.

Plant drying machines contribute to food safety, extend shelf life, and support modern farming operations, making them a valuable investment. By embracing these machines, farmers can ensure that their products reach consumers in the best possible condition, contributing to a more successful and resilient agricultural supply chain.